Introduction to Heating And Stirring Mantles

In modern laboratories, precision, safety, and efficiency are non-negotiable. When it comes to heating solutions, Heating And Stirring Mantles have become indispensable tools for chemists, researchers, and technicians. Unlike traditional Bunsen burners or hot plates, these specialized devices provide controlled, uniform heating while also enabling magnetic stirring of liquids. This makes them perfect for sensitive experiments where accuracy is key.

Whether you’re working in academic research, pharmaceuticals, or industrial applications, understanding how these mantles work can help you choose the right equipment and improve your experimental results.

What Are Heating And Stirring Mantles?

Basic Definition

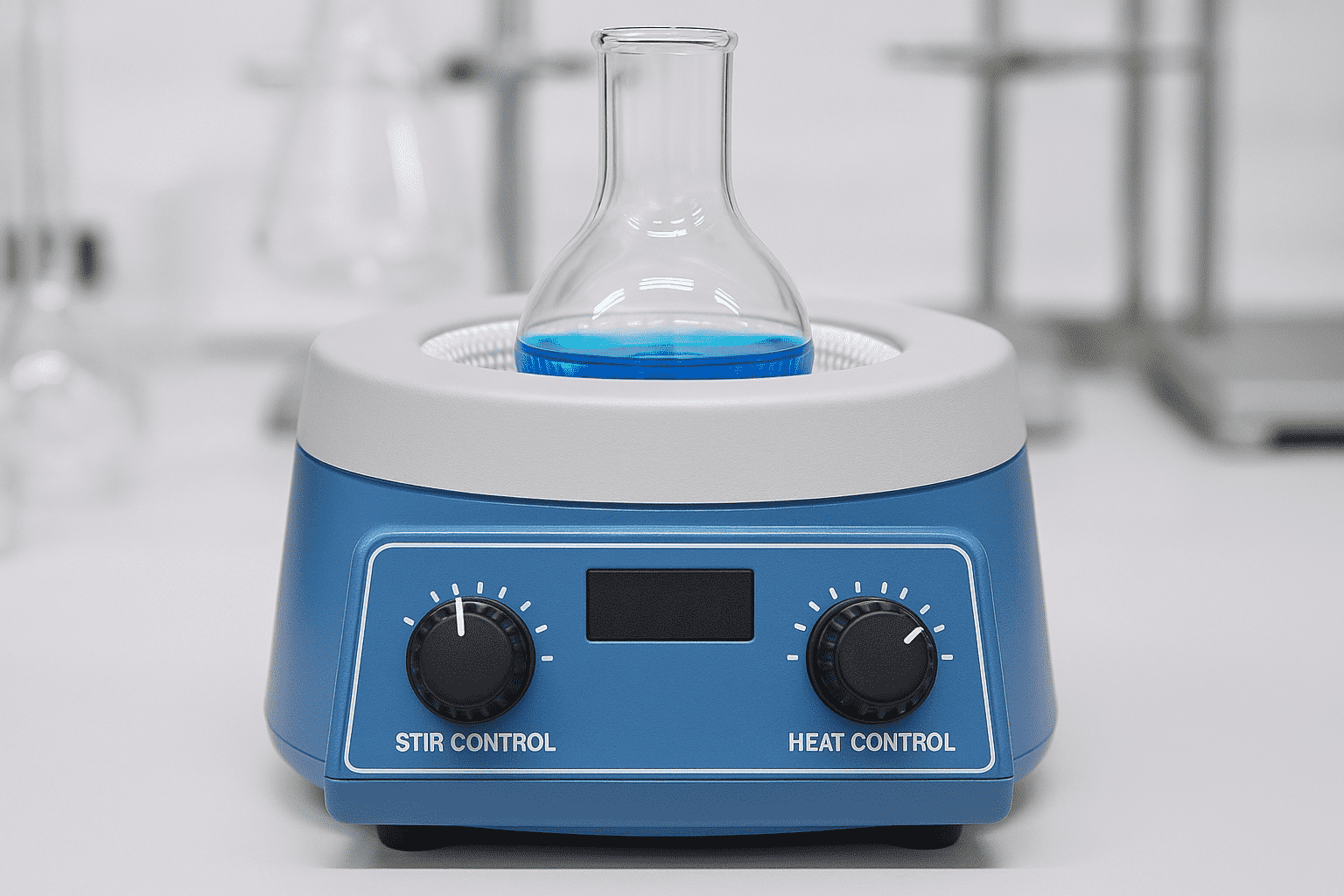

Heating and stirring mantles are laboratory devices designed to heat glassware, typically round-bottom flasks, and simultaneously stir liquid solutions using a magnetic stirrer.

Historical Development

Before their invention, labs relied on open flames or water/oil baths, which posed risks of uneven heating and contamination. The introduction of electric mantles in the mid-20th century revolutionized lab heating, offering safer, cleaner, and more precise temperature control.

How Heating And Stirring Mantles Work

The Heating Mechanism

A mantle contains heating elements woven into a fabric shell that wraps snugly around the flask. This design ensures even distribution of heat and prevents “hot spots.”

The Stirring Function

The stirring feature uses a magnetic stir bar placed inside the liquid. A rotating magnet under the mantle synchronizes with the stir bar, ensuring uniform mixing throughout the experiment.

Types of Heating And Stirring Mantles

Heating Mantles

These provide heating only. They are commonly used when stirring isn’t required.

Stirring Mantles

Designed exclusively for stirring, they don’t provide heat but are useful for mixing solutions at room temperature.

Combined Heating & Stirring Mantles

The most versatile option, these allow simultaneous heating and stirring—ideal for chemical reactions and distillations.

Applications of Heating And Stirring Mantles

Chemical Laboratories

Used for organic synthesis, distillations, and extractions where precise heating and mixing are crucial.

Pharmaceutical Research

Essential for preparing formulations, testing drug stability, and carrying out controlled reactions.

Industrial Applications

Applied in chemical manufacturing, food processing, and material testing, ensuring consistent product quality.

Advantages of Using Heating And Stirring Mantles

Safety and Efficiency

Unlike open flames, mantles reduce fire hazards and are safer to use with volatile solvents.

Precision in Temperature Control

Many modern mantles feature digital temperature displays, allowing for highly accurate heat regulation.

Uniform Heat Distribution

Their design ensures the entire flask surface is heated evenly, improving experimental outcomes.

Limitations and Precautions

Common Issues and Solutions

-

Mantle overheating due to improper settings → Use thermostats.

-

Uneven stirring → Check stir bar size and placement.

Safety Precautions in Use

-

Always use appropriate glassware.

-

Avoid spills to protect the heating elements.

-

Never leave the mantle unattended during operation.

Key Features to Look for in Heating And Stirring Mantles

Capacity and Volume

Choose a mantle that fits your flask size—ranging from 50 mL to 20 L.

Digital vs. Analog Controls

Digital mantles offer more accuracy, while analog models are cost-effective and easier to operate.

Temperature Range and Stability

Select a model that covers your required temperature spectrum, often up to 450°C.

How to Maintain Heating And Stirring Mantles

Cleaning and Care Tips

-

Wipe surfaces with a damp cloth (avoid harsh chemicals).

-

Store in a dry environment.

-

Avoid overloading with oversized flasks.

Troubleshooting Common Problems

-

If heating is inconsistent → Check for faulty wiring.

-

If stirring stops → Inspect the magnetic drive system.

Buying Guide for Heating And Stirring Mantles

Factors to Consider Before Purchase

-

Flask capacity

-

Control type (digital/analog)

-

Temperature range

Where to Buy

You can buy Heating And Stirring Mantles from trusted manufacturers, suppliers, and exporters in India. For premium-quality Heating And Stirring Mantles, Simson Chemtech is a leading manufacturer and supplier in India.

Conclusion

Heating and stirring mantles have transformed laboratory operations, offering safe, efficient, and precise solutions for heating and mixing tasks. From chemical labs to industrial facilities, their applications are vast and growing. Whether you’re setting up a new lab or upgrading your equipment, investing in a high-quality mantle can significantly enhance your research and productivity.

FAQs About Heating And Stirring Mantles

Q1. What is the difference between a hot plate and a heating mantle?

A heating mantle provides more uniform heating and is safer for flasks than hot plates.

Q2. Can I use any type of flask with a heating mantle?

Round-bottom flasks are recommended, as they provide maximum contact and safety.

Q3. How do I choose the right size mantle?

Match the mantle size to your flask volume for efficiency and safety.

Q4. Can heating mantles handle corrosive chemicals?

Yes, but ensure proper glassware and ventilation are used to avoid damage.

Q5. Do stirring mantles work without a stir bar?

No, a magnetic stir bar is necessary for mixing.

Q6. How long do heating and stirring mantles last?

With proper care, they can last 5–10 years depending on usage frequency.